I’ve done a lot of full-bleed printing in my time, even having produced and published a 100-page monthly magazine at one point in my career. While that type of printing requires a considerable amount of hardware and material handling (perfect binding, etc.) there are full bleed printing jobs that could be better served in-house—with the right equipment. These are smaller-run print jobs that either need to be done more quickly, or which may not qualify for the large minimum prints that are typically associated with going out of house for the traditional offset job. This type of edge-to-edge printing is more common than you may think, and it brings up an interesting question: Can certain businesses and organizations benefit by bringing these jobs in-house? And, are there toner-based laser printers that can even provide full-bleed printing?

To answer that question, we spoke with Kent Villarreal, senior product manager of high volume products at Sharp Electronics Corp. He gave me a small peek into the world of light production printers and how and where these new models from Sharp can really change the way printing is done. It’s largely thought that laser printing and toner technology cannot provide full bleed or edge-to-edge printing, but that’s no longer the case. Let’s take a look at a few examples of how these new toner-based laser printers offer a lot of opportunity:

Benefitting from Light Production Full Bleed Printers

The Trade Show Product or Service Announcements

Trade shows are a big opportunity for many companies and organizations to debut and test out new ideas, products, or services. The thing is, there are lots of times when these ideas have yet to receive final refinement and tweaking. That means that while there may be a need for 500 full color brochures at the show, a company may not be ready to print the 10,000 or more required to break even and satisfy the eventual needs for distributing the final materials to dealers and partners. Plus, a tradeshow roll-out of a print package may yield some insights which can then be used to refine the final product. An in-house full bleed light production machine can handle this sort of preliminary print job—along with all of the other in-house edge-to-edge printing duties that are required of it. For these smaller “advance” runs, this type of product is going to make a lot of sense for many companies and organizations.

Trade shows are a big opportunity for many companies and organizations to debut and test out new ideas, products, or services. The thing is, there are lots of times when these ideas have yet to receive final refinement and tweaking. That means that while there may be a need for 500 full color brochures at the show, a company may not be ready to print the 10,000 or more required to break even and satisfy the eventual needs for distributing the final materials to dealers and partners. Plus, a tradeshow roll-out of a print package may yield some insights which can then be used to refine the final product. An in-house full bleed light production machine can handle this sort of preliminary print job—along with all of the other in-house edge-to-edge printing duties that are required of it. For these smaller “advance” runs, this type of product is going to make a lot of sense for many companies and organizations.

The University or Campus-wide Educational Institution

For a university or other educational institution that covers a lot of ground (both literally and figuratively), the ability to self-produce full bleed printing materials for brochures, graduation events and department communications is a transforming advancement that can reap instant rewards and quickly create a return on investment that is staggering. From fliers to pamphlets to handbooks and other saddle-stitch bound materials, using a light production printer is a lot like having your own press in-house.

Small Print Shops and Reprographics Companies

Smaller print shops can often find they can revolutionize the way they do business by offering low cost alternatives to more expensive offset printing. This is particularly true for lower-volume jobs and projects which require a quick turnaround. By providing full bleed edge-to-edge printing without the need for plates or expensive setup processes, light production printers can offer much in the way of opportunities for these companies to really provide services at prices that were unheard of just a few years ago.

A New Type of Light Production Printer for Full Bleed Printing

Not too long ago (in the world of print) Sharp launched a couple of color products into the high volume space. These were the MX-6240N and the MX-7040N. The products were built using a brand new engine platform that was developed from the ground up. Now, these are high volume printers that can support up to 250,000 pages or more per month, and they bridge a very important gap between the true digital press products and the more traditional workgroup machine. But there was still something that could bridge the gap further: a light production printer with full bleed, edge-to-edge color capabilities. So, how do you achieve edge-to-edge printing at that scale without a traditional offset process?

Sharp claims to have solved that dilemma with the Pro Series Color Document Systems (specifically, the MX-6500N and the MX-7500N, which offer 65 ppm and 75 ppm respectively). These products were punctuated by three specific features:

Edge-to-Edge Full Bleed Printing from a Laser Printer

Until these products came out, you really couldn’t print full bleed with a toner-based printer—and certainly not with any toner-based printer that could support a light production environment. As of right now (as far as we’re aware), no one except Sharp prints edge to edge on a competitive device. There are physical and mechanical limitations to putting toner to the edge of paper and running it through a toner based machine – it just doesn’t work. This is typically a roller mechanism. Sharp has found a way around that and can produce color prints with full bleed on up to 11×17 tabloid stock. Combined with an optional finisher, that means you can output saddle-stitched brochures, folded booklets, and full-color newsletters off of the same machine.

EFI Fiery Command Workstation Software

Sharp fully integrated the Fiery Command Workstation job management software into the new Pro Series Document Systems. This is significant because you no longer have to use an external workstation to manage your print jobs. You can bring everything up on the 15.4″ touchscreen display located right on the unit. Normally, you would have to submit the job, and then have an authorized print manager set it up. Now, you can just pull out the full-sized pivoting keyboard or use the touch screen interface to get everything started. It really streamlines your workflow.

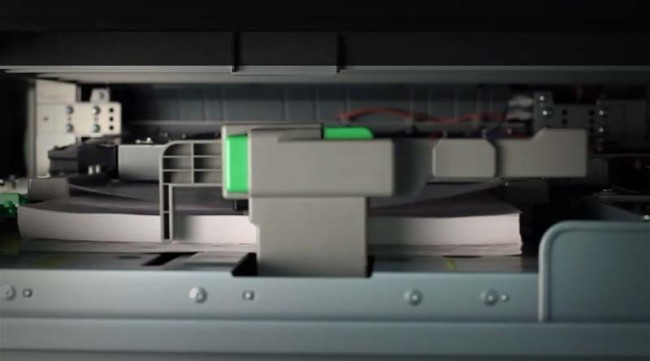

Pneumatic Paper Feed System

If you thought pneumatics were just for putting nails into houses, think again. Sharp set up a pneumatic paper feed system that blows in three different directions to separate the paper from the stack and vacuum feed it into the machine. The system all but eliminates issues with coated or textured paper, and it’s virtually maintenance-free since there are no feed rollers.

How Do You Get Full Bleed Printing Without an Offset Process?

We alluded to this above, but one of the biggest breakthroughs in the process was when Sharp eliminated the need for feed rollers to get the paper into the machine. That meant devising a new way to lift the page from the stack. Their solution was to use a pneumatic triple air feed system that is a maintenance-free method of feeding paper with thicknesses of up to 110 lb cover stock through the machine. Combined with a maximum feed capacity of 13,500 sheets, and the Pro Series took on a new role as an offset press-killer—at least for smaller print jobs and projects requiring a fast turnaround.

In the Sharp Pro Series, full bleed booklets are performed by printing edge to edge across the short edge of an 11×17 inch sheet size. The machine has been designed to accommodate printing to the edges of the paper by employing proprietary cleaning, fusing and transfer mechanisms. There is still the required lead edge and trail edge voids so that the sheet does not stick to the fuser—and with only a face trim option in the saddle finisher you accomplish the full bleed booklet.

Conclusion

Until now, full-bleed printing was constrained to small, inkjet printers or high-volume digital press machines. The latter takes multiple steps in offline digital printing or involves bulky and costly options. Traditionally, laser printers or toner-based printers simply don’t offer full-bleed printing. If you want to do this type of full-bleed printing in-line, your options were slim to none. Even if you could find something to accomplish the work, it would add an additional 10 feet or more to the footprint of the machine and be expensive—not an option for most In-Plant/CRDs that operate with limited space and tight budgets.

Until now, full-bleed printing was constrained to small, inkjet printers or high-volume digital press machines. The latter takes multiple steps in offline digital printing or involves bulky and costly options. Traditionally, laser printers or toner-based printers simply don’t offer full-bleed printing. If you want to do this type of full-bleed printing in-line, your options were slim to none. Even if you could find something to accomplish the work, it would add an additional 10 feet or more to the footprint of the machine and be expensive—not an option for most In-Plant/CRDs that operate with limited space and tight budgets.

Now, Sharp is opening up a whole new world of light production that may just transform the way larger organizations and campuses handle their print jobs. As more and more companies look to save on marketing production costs, full bleed color laser printing could be the solution to transform and even revolutionize the industry. Of course, small businesses will be chomping at the bit to see if this kind of technology can be reduced and scaled to work with smaller workgroup-level products. We’ll have to wait and see if that’s a possibly trickle-down over the next decade. If so, the offset printing industry will be in for quite a shock!

Click here for more information from Sharp.

CopierGuide Copier and Multifunction Printer Leases and Reviews

CopierGuide Copier and Multifunction Printer Leases and Reviews

You nailed it right on te head. In some circumstances this model is a gamechanger.

It does, however, achieve a full bleed 11×17 booklet by printing edge to edge on the long side. You indicated it was on the short edge. 🙂

Thanks for the article!

Kat